information

项目名:宜宾亚克力五粮液酒瓶

年份:2023年

地点:宜宾

设计: 汤臣新材

Project Name: Yibin Wuliangye Bottle

Year: 2023

Location:

Design: Donchamp

酒瓶文化是中国酒文化的重要组成部分,原始时期至商周酒器以天然材料(竹、木、匏、兽角)和陶器为主,秦汉至明清经漆器、玉器兴盛后,瓷器成为主流,民国后玻璃瓶逐步取代陶瓷,最为经典的就是五粮液,以1973年成为主流且沿用至今的弧形萝卜瓶为典型代表。

The culture of wine bottles is an important part of Chinese wine culture. From the primitive period to the Shang and Zhou dynasties, wine vessels were mainly made of natural materials (bamboo, wood,animal horns) and pottery. From the Qin and Han dynasties to the Ming and Qing dynasties, after the prosperity of lacquerware and jade, porcelain became the mainstream. After the Republic of China, glass bottles gradually replaced ceramics. The most classic is Wuliangye, represented by the curved radish bottle that became mainstream in 1973 and is still in use today.

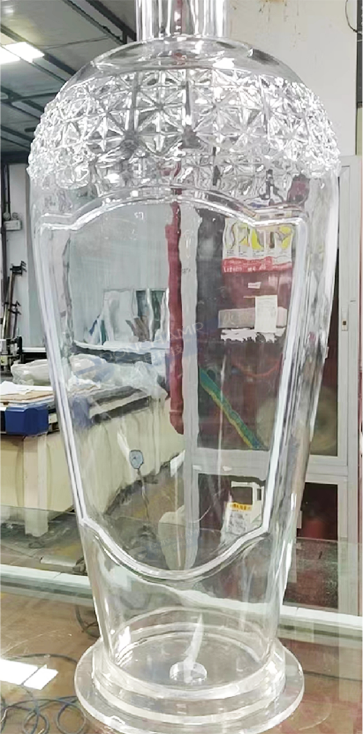

而今,汤臣科技将这一经典设计通过透明亚克力材质焕发新生,1:1等比还原,将五粮液萝卜瓶转化为巨型景观装置,在宜宾站台矗立起一座“透明的文化纪念碑”。

Now, Donchamp Technology has revitalized this classic design through transparent acrylic material, restoring it in a 1:1 ratio and transforming the Wuliangye radish bottle into a giant landscape installation. A "transparent cultural monument" has been erected on the Yibin platform.

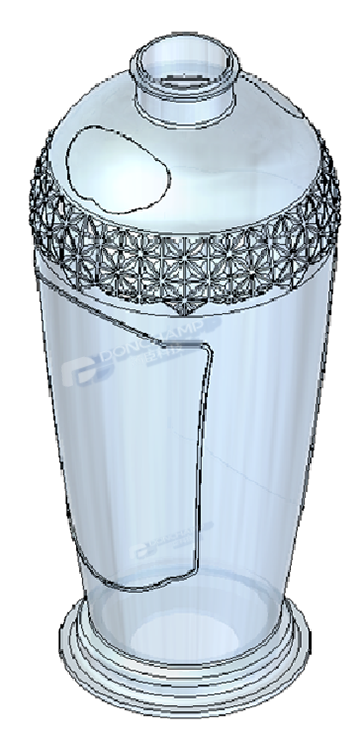

整个产品高12米,直径4.5米,重12.8吨,瓶身使用50mm厚的亚克力加工而成,瓶身为双曲面结构,表面造型存在大量不规则三角形花纹,产品恢弘大气,彰显汤臣技术。

The entire product is 12 meters high, 4.5 meters in diameter, and weighs 12.8 tons. The bottle body is made of 50mm thick acrylic processing, and the bottle body has a hyperbolic structure with a large number of irregular triangular patterns on the surface. The product is grand and magnificent, showcasing the technology of Tangshan.

为何选择亚克力?

其中有个小插曲。终端客户原本选择了PC板,然一年后板材发黄,严重影响五粮液的品牌形象宜宾风貌,汤臣亚克力兼具玻璃的通透与工程塑料的可塑性,又克服了二者的局限:

Why choose acrylic? There is a small interlude among them. The end customer originally chose PC board, but after a year, the board turned yellow, seriously affecting the brand image of Wuliangye and the style of Yibin Tangchen Acrylic combines the transparency of glass and the plasticity of engineering plastic, overcoming the limitations of both:

(1)抗黄变:

汤臣TC-1系列板材(厚板)通过15000小时快速老化试验,抗黄变性能佳;

Anti aging: Tomson TC-1 series plates (thick plates) have passed the 15000 hour rapid aging test, with good anti-aging performance;

(2)无缝拼接技术:

传统玻璃受限于切割弧度,汤臣采用本体聚合工艺,使多块亚克力复合成型后“无接痕”,精准还原萝卜瓶的弧形曲面。

Seamless Polymerization:Traditional glass is limited by cutting curvature, so Donchamp adopts a raw-pulp polymerization to make multiple pieces of acrylic composite "seamless" after molding, accurately restoring the curved surface of the radish bottle.

(3)安全承重设计:

项目整个瓶身为不规则柱状结构,瓶身整体通透,无内部钢结构或木结构支撑,针对大型景观结构,汤臣通过力学测算板材厚度与支撑方案,确保其不变形。

Safe load-bearing design: The entire bottle body of the project is an irregular columnar structure, which is transparent as a whole and has no internal steel or wooden structure support. For large landscape structures, Tangchen calculates the thickness of the board and the support scheme through mechanics to ensure that it does not deform.

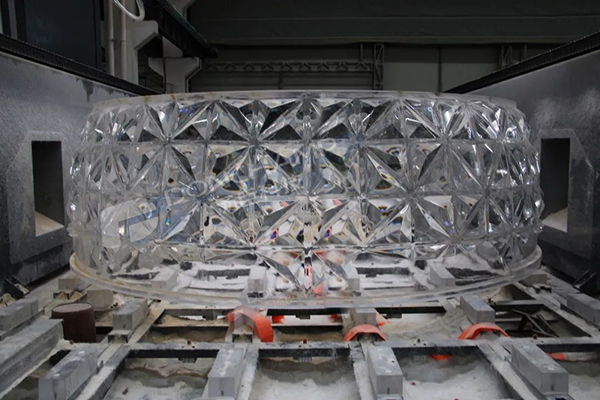

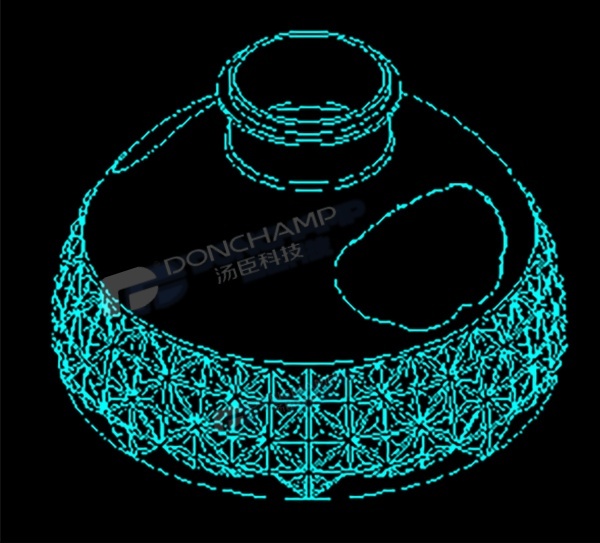

五粮液瓶身三角鳞状花纹部分作为此景观项目造型特色之一,从前期三维模型的建立就带来了一定的挑战。

The triangular scale pattern on the body of Wuliangye bottle, as one of the distinctive features of this landscape project, has posed certain challenges since the establishment of the 3D model in the early stage.

汤臣旗下子公司汤臣新材工艺和设计师凭借精湛的技术和敏锐的洞察力,利用客户提供的五粮液经典瓶实物进行细致的测量。

Donchamp Technology and designers, rely on exquisite technology and keen insight to conduct detailed measurements using the classic Wuliangye bottles provided by customers.

除此之外,实际加工过程中的工艺和模型建立、繁杂的雕刻、复杂的曲率等问题也为制模和拼接带来困难。

In addition, the problems of process and model establishment, complex carving, and complex curvature in the actual processing also bring difficulties to mold making and splicing.

面对这些难题,汤臣展现出了其强大的专业实力。公司拥有经验丰富的深化设计团队和工程团队,他们在亚克力相关工艺和技术方面有着深厚的积累。凭借丰富的项目经验,团队能够提前预见并解决可能遇到的问题,建立联动响应机制,确保整个加工制作流程的顺利进行。

Faced with these challenges, Tang Chen demonstrated his strong professional strength. The company has an experienced deepening design team and engineering team, who have profound accumulation in acrylic related processes and technologies. With rich project experience, the team is able to anticipate and solve potential problems in advance, establish a linkage response mechanism, and ensure the smooth progress of the entire manufacturing process.